As consumer demand grows for both healthier options and more indulgent, innovative chocolates, the need to adapt to new regulations, trends, and technologies is paramount. Whether you are looking to comply with the latest regulations, such as the EUDR and Cadmium regulations, or expand into new markets with hyper-indulgent offerings, strategic product decisions can significantly influence your ability to stay ahead.

The decisions made at this stage—whether related to certifications, new product formulations, or investment in technology upgrades—will determine your company’s future. By understanding how to balance regulatory compliance, market-driven consumer needs, and production capabilities, you will be better positioned to innovate while scaling operations effectively.

|

⭐Key Takeaway: For CEOs, founders, and decision-makers in chocolate manufacturing, this blog will guide you through five critical variables that should shape your product decisions and help you stay competitive in a dynamic market. |

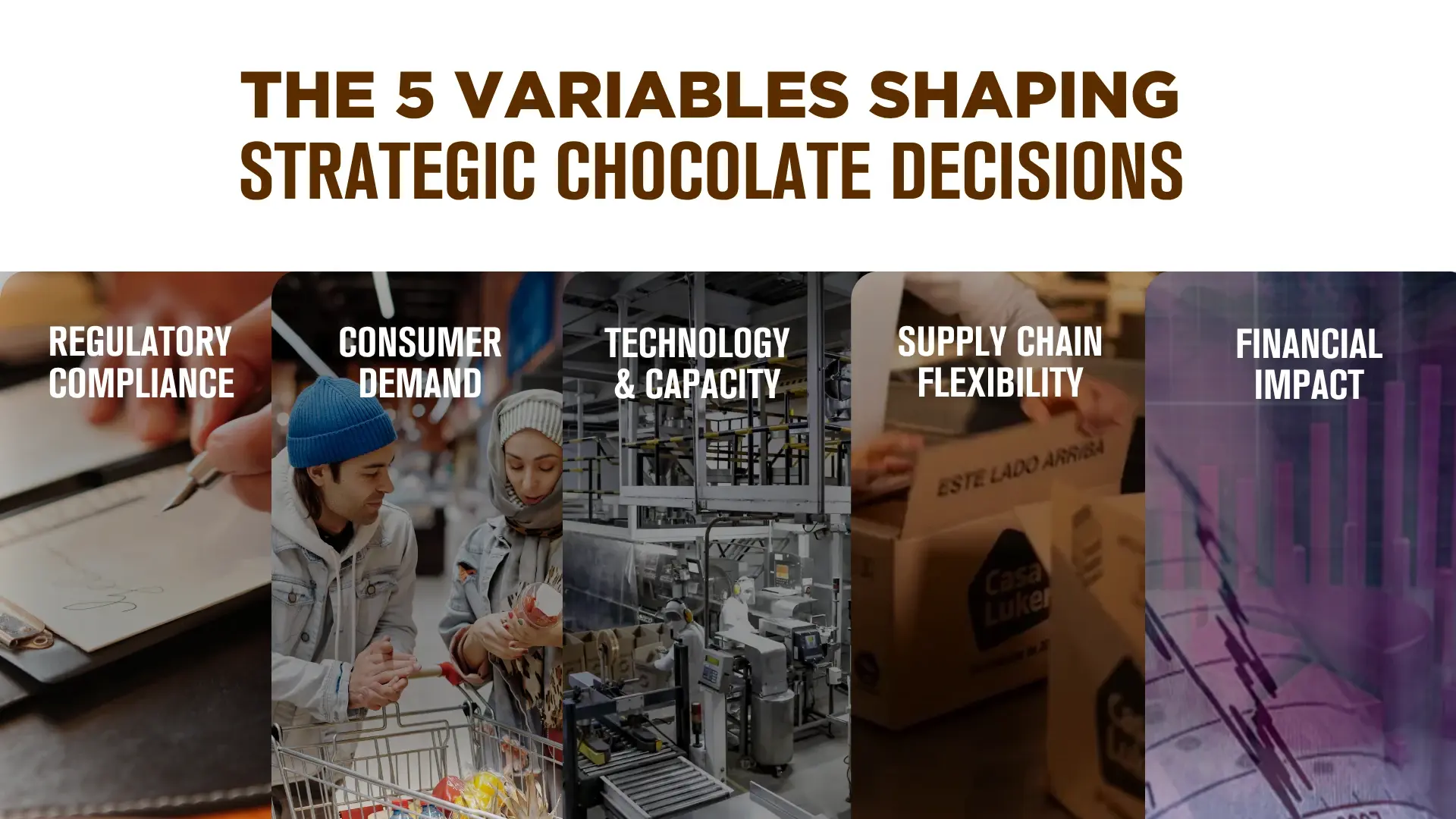

This blog will break down five essential variables that you should consider when making strategic decisions about your products. These variables cover everything from regulatory compliance to understanding the balance between health-conscious options and hyper-indulgent formulations, as well as the need to invest in technology for scaling production.

Table of Contents:

- Variable 1: Regulatory Changes and Compliance – A Growing Priority

- Variable 2: Consumer demand shifts

- Variable 3: Technology and Production Capacity – Finding the Right Balance

- Variable 4: Supply Chain Flexibility – From Partners to Traceability

- Variable 5: Financial Impact – CAPEX, ROI, and Scaling Decisions

- Practical Tips for Making Strategic Product Decisions

Variable 1: Regulatory Changes and Compliance

In the ever-evolving landscape of the chocolate industry, regulatory compliance is becoming one of the most significant factors shaping product decisions. Whether you're dealing with the EU Deforestation Regulation (EUDR), Cadmium regulations, or certifications such as Kosher or B Corp, understanding and integrating these regulations into your product strategy is critical for long-term success.

Regulatory demands affect not just product formulations but also how your manufacturing processes are designed, scaled, and managed. As a result, decision-makers need to prioritise compliance as an integral part of their product strategy, rather than as an afterthought.

What Chocolate Brands Need to Know About EUDR, Certifications and Traceability:

- New Regulations are constantly emerging, with initiatives such as the EU Deforestation Regulation (EUDR) and cadmium levels leading the charge in shaping sustainable cocoa sourcing. Compliance will be mandatory for brands exporting to the EU, with deadlines fast approaching. These regulations demand transparency and traceability in your supply chain—requirements that may affect everything from your chocolate sourcing to your final product packaging.

- Certifications Drive Consumer Trust: Certification systems like Kosher and Organic continue to grow in importance. Many consumers now consider certification labels as essential decision-making factors when choosing products. For brands, obtaining and maintaining certifications requires investing in technology and process adaptation. Additionally, the investment in systems that enable supply chain traceability and data verification must be incorporated into your planning process.

- Anticipating Regulatory Changes Is Crucial: Rather than waiting for regulations to take effect, forward-thinking companies invest in R&D and production upgrades to future-proof their operations. Proactive planning allows companies to manage risk and stay ahead of compliance deadlines.

Actionable Tips:

- Review Current and Upcoming Regulations: Identify all relevant regulations that will impact your production over the next 1-3 years, and develop a compliance strategy based on these regulations. For example, the EUDR requires all cocoa products exported to the EU to be deforestation-free, impacting both sourcing and traceability.

- Invest in Traceability Systems: Ensure your cocoa sourcing and production processes are transparent and traceable. Systems like Luker Trace are designed to track every batch of cocoa and ensure compliance with international standards.

- Stay Ahead of the Curve: Don't wait until compliance deadlines are upon you. Invest in process upgrades, such as more sustainable sourcing models or automated traceability tools, to ensure your operations meet the evolving demands of global markets.

- Certification Strategy: Identify the certifications that matter most to your brand’s target markets (e.g., Rainforest Alliance for ethical sourcing or Kosher for product inclusivity). Plan for the costs, processes, and timelines needed to achieve and maintain these certifications.

| What You Need to Know: Brands must understand and align their operations with current and emerging regulations. By building compliance into your product strategy, you'll mitigate risk, enhance your product’s value in the eyes of consumers, and ensure you're prepared for the future. |

💡 Ready to future-proof your product offerings?

Our team can help you navigate evolving regulations and implement compliance strategies that suit your product line. Contact us to explore our turnkey manufacturing solutions, which incorporate sustainability and traceability for seamless regulatory compliance.

Variable 2: Meeting Market Demand – Balancing Health with Indulgence

One of today’s key challenges in chocolate innovation is striking a balance between health-conscious trends (e.g., low-sugar, plant-based, protein-rich products) and the strong demand for indulgent experiences. Consumers want chocolates that combine functional benefits with indulgence, or those that heavily deliver on novel flavours, exciting textures, and luxurious experiences.

Product development teams must be agile, creatively integrating in-demand ingredients and claims (such as adaptogens, prebiotics, proteins, plant-based, and low-sugar) and indulgent elements (like caramel, nougat, and ganaches) into innovative formats. Brands that master this balance stand out by offering chocolates that appeal to both wellness-focused consumers and those seeking premium indulgence.

|

👀Good-to-know In 2024, 62% of North American consumers were actively seeking chocolates with lower sugar content and added protein, highlighting the rise of health-conscious chocolate options (Innova Market Insights). At the same time, indulgent chocolates with unique inclusions and new flavours are leading the way in both premium and mass markets, with demand for hyper-indulgence soaring, especially among Millennials and Gen Z. |

💡How to Innovate with Flavour, Texture and Functionality in Indulgent Chocolate

- Experiment with new flavours and ingredients: Don’t be afraid to blend health benefits with indulgent flavours. Ingredients like adaptogens (e.g., ashwagandha) or functional inclusions (e.g., collagen or prebiotics) can be paired with traditional indulgent flavours like caramel, hazelnut, or cherry to create unique products.

- Leverage texture innovation: Consumers crave textural variety in their indulgence experiences—think crunchy inclusions, gooey fillings, or smooth creams. Work with your manufacturing partner to ensure you can achieve these textures without compromising the flavour.

- Create protein-enriched indulgence: The market for high-protein chocolate is expanding, but the real challenge is keeping the chocolate’s indulgent mouthfeel while offering functional benefits. Use protein blends like whey and plant-based proteins to provide creaminess and satiety without sacrificing the pleasure of eating chocolate.

- Don’t neglect premium formats: Offering premium product formats like multi-layered bars, filled chocolates, or truffle-style formulations can add a luxurious element to your product and attract consumers who want to experience pleasure and wellness.

| What You Need to Know: The demand for healthier options and more indulgent formats is not contradictory—it’s complementary. The key is to leverage innovation in both product formulation and the consumer experience, ensuring that each product strikes a balance between functional benefits and indulgent pleasure. |

Variable 3: Technology and Production Capacity for Strategic Scaling and Flexibility

Strategically upgrading your technology and production capacity is vital to keep pace with market demands, product innovation, and regulatory shifts. Whether investing in adaptable equipment or partnering with turnkey manufacturers, aligning production capabilities with your strategic goals ensures quality, consistency, and scalability, enabling your brand to effectively seize emerging opportunities.

For brands, especially, a strategic approach might mean partnering with a turnkey manufacturer. This path enables brands to rapidly scale without incurring significant upfront capital expenditures (CAPEX) on equipment or facilities. Such strategic partnerships enable you to focus on innovation, marketing, and brand-building, while the manufacturing partner handles quality, consistency, and scalability.

Why It Matters for Your Product Decisions:

- Meeting Emerging Consumer Demand:

As trends emerge—such as indulgent chocolates with novel fillings or health-oriented ingredients like high-protein or reduced-sugar formulations—your current production lines may lack the necessary flexibility or capacity. Investing in adaptable technology or collaborating with a turnkey partner ensures your products quickly adapt to these new market opportunities. - Maintaining Quality and Consistency at Scale:

Consumers demand consistently high-quality experiences, especially when paying premium prices for innovative chocolate products. Upgrading to modern production technology ensures your chocolate maintains its intended taste, texture, and functionality—even at significantly increased volumes. - Compliance and Sustainability:

Modern technology investments also address regulatory requirements, such as supply-chain traceability mandated by the EU Deforestation Regulation (EUDR) and standards related to heavy metals (e.g., Cadmium regulations). Advanced manufacturing solutions now often integrate digital tracking, real-time quality monitoring, and precise ingredient management, enhancing your overall compliance and sustainability efforts.

How to Future-Proof Your Chocolate Manufacturing with the Right Tech and Partnerships:

- Audit Your Current Production Capabilities:

- Evaluate your existing machinery against your planned product innovations. Identify bottlenecks, limitations, or outdated processes that could delay product launches or limit innovation.

- Prioritise critical investments in technology that enhance quality assurance, regulatory compliance (such as traceability systems), and flexibility (e.g., versatile tempering or enrobing equipment).

- Explore Strategic Turnkey Manufacturing Partnerships:

- Evaluate external manufacturing partners who offer not just additional capacity but specialised expertise in areas like protein incorporation, complex inclusions, or advanced chocolate tempering.

- Ensure alignment with your brand’s values and verify that your partner holds essential certifications (Kosher, Organic, Rainforest Alliance) and sustainability credentials to reinforce your market positioning.

- Invest in Flexible and Scalable Technology Solutions:

- Choose versatile production equipment capable of handling various product formulations, textures, and inclusions (e.g., advanced tempering machines capable of processing different viscosities and textures).

- Adopt Industry 4.0 technologies such as digital real-time data monitoring, automated quality control, and predictive maintenance to streamline production and maintain high-quality standards.

- Pilot Test Before Large-Scale Implementation:

- Run smaller-scale pilot batches when testing new technologies or working with new partners to validate your formulations and ensure product integrity before scaling up to full-scale production.

- Use pilot testing to confirm consumer acceptance, production efficiency, and consistency, enabling you to scale your operations with confidence.

|

What You Need to Know: By carefully aligning your manufacturing capabilities and strategic partnerships with your business goals, your chocolate brand can quickly respond to shifting market demands, maintain product consistency, and effortlessly meet regulatory standards. Thoughtful technology investment—or strategic turnkey partnerships—empowers your brand to innovate efficiently, scale sustainably, and focus resources on customer engagement, differentiation, and growth. |

💡 Ready to strategically scale your chocolate production?

Explore our Turnkey Manufacturing Solutions, designed specifically for brands seeking rapid, efficient scaling combined with innovation support and full regulatory compliance.

Variable 4: Supply Chain Flexibility – From Partners to Traceability

Building a flexible and responsive supply chain is crucial for adapting quickly to market changes, regulatory shifts, and evolving consumer expectations. Strong supplier relationships, robust traceability, and the ability to swiftly pivot in sourcing practices can determine your chocolate brand’s ability to innovate and scale effectively.

Why It Matters for Your Product Decisions:

- Adaptation to Market Demands:

With growing consumer preferences for sustainably sourced and certified products (e.g., Organic, Kosher), brands must ensure that their suppliers align with these expectations. A flexible supply chain allows for quick adjustments, ensuring you remain competitive and appealing to discerning consumers. - Traceability and Regulatory Compliance:

Regulations like the EUDR require robust traceability proving deforestation-free sourcing. A transparent and adaptable supply chain helps you comply smoothly, reducing the risk of market disruption and enhancing consumer trust. - Risk Management:

Climate impacts, geopolitical factors, and supply-chain disruptions require proactive management. Diversified supplier networks and flexible sourcing strategies help mitigate risks, ensuring stable product availability and consistent quality.

How to Build a Reliable and Compliant Supply Chain for Chocolate Manufacturing:

- Diversify Your Supplier Network:

- Identify and qualify alternative suppliers to reduce reliance on single-source providers.

- Ensure each supplier meets necessary certifications and sustainability standards relevant to your markets.

- Invest in Robust Traceability Solutions:

- Implement traceability platforms, such as Luker Trace, enabling detailed tracking of ingredient origins and certifications.

- Utilise digital traceability tools for real-time visibility and compliance verification.

- Build Strategic Supplier Partnerships:

- Collaborate closely with suppliers to ensure alignment on sustainability goals, certification compliance, and ingredient quality standards.

- Foster long-term relationships through transparent communication and shared value creation.

- Regularly Audit and Reassess Supply Chain Risks:

- Conduct periodic audits of your suppliers’ practices, certifications, and compliance levels.

- Stay proactive by planning for potential disruptions, regulatory changes, or market shifts.

What You Need to Know:

Prioritising strong supplier partnerships and robust traceability solutions enhances your ability to innovate, remain compliant, and deliver consistent quality. A flexible, transparent, and strategically managed supply chain empowers your chocolate brand to swiftly adapt to evolving market and regulatory demands.

💡 Discover how our sustainable sourcing and turnkey solutions can help your brand stay agile, compliant, and responsive to market needs.

Variable 5: Financial Impact – CAPEX, ROI, and Strategic Fit

Evaluating the financial implications of your strategic product decisions—particularly those related to capital expenditures (CAPEX), return on investment (ROI), and alignment with brand strategy—is critical. Every decision should strike a balance between immediate financial outcomes and long-term strategic value, as well as brand alignment, to ensure sustainable growth and market competitiveness.

Strategic financial assessment helps prioritise investments effectively, ensuring your resources support not just immediate gains but also build lasting competitive advantages. Carefully weighing short-term benefits against long-term impact allows your brand to confidently scale, innovate, and remain agile amidst shifting market demands and regulatory landscapes.

Why It Matters for Your Product Decisions:

- Prioritising Investments:

Limited resources require careful prioritisation of projects. Assessing potential returns, strategic benefits, and associated risks ensures your investments align with both market opportunities and your brand’s long-term vision. - Optimising Resource Allocation:

Properly evaluating CAPEX decisions helps direct resources toward initiatives with the highest impact—such as equipment upgrades, technology improvements, or new product innovations—maximising overall operational efficiency and profitability. - Strategic Alignment:

Ensuring that product decisions clearly align with your brand’s core identity and future strategy prevents costly diversions. Projects should reinforce your positioning, whether that’s as an innovator in indulgence, offering health-conscious options, promoting sustainability, or providing premium quality.

How to Prioritise Chocolate Innovation Projects for Maximum Strategic Impact:

- Use a Decision Matrix for Evaluation:

- Evaluate each potential project based on criteria like ROI, strategic alignment, market demand, compliance impact, and risk mitigation.

- Quantify and rank projects systematically to objectively prioritise investments.

- Balance Short- and Long-Term ROI:

- Identify quick-win opportunities (e.g., process improvements) alongside strategic long-term investments (e.g., technology upgrades or turnkey partnerships).

- Aim for a balanced project portfolio that delivers immediate returns and builds long-term capabilities.

- Involve Cross-Functional Teams in Financial Planning:

- Collaborate with finance, R&D, production, and marketing teams to ensure a comprehensive project benefits and feasibility assessment.

- Regular communication ensures alignment between financial planning and operational realities, as well as strategic goals.

- Allocate Budget Flexibly:

- Keep an innovation or contingency fund available to respond to unexpected market opportunities or regulatory shifts quickly.

- Flexible financial planning helps your brand remain agile and resilient.

What You Need to Know:

Integrating a thorough financial evaluation into your decision-making process ensures strategic alignment, effective resource utilisation, and sustainable growth. By systematically assessing ROI, CAPEX, and long-term strategic fit, your chocolate brand can confidently navigate market shifts and leverage opportunities effectively.

Next steps for strategic chocolate product decision-making

In today’s dynamic chocolate market, strategic product decision-making is more critical than ever. Navigating the complexities of regulatory compliance, consumer-driven market shifts, advanced production capabilities, supply chain flexibility, and financial implications requires a straightforward, structured approach.

By focusing on the five variables outlined—regulatory compliance, consumer demand shifts, technology and scaling, supply chain agility, and financial impact—your brand can confidently prioritise projects that deliver both immediate value and long-term growth. Remember, successful decision-making is not only about choosing what to pursue, but also about clearly identifying what to defer or avoid.

In an environment where consumer expectations evolve rapidly and regulations continuously tighten, proactively addressing these strategic variables ensures your chocolate brand is always prepared, competitive, and capable of turning challenges into meaningful opportunities.

|

Variable |

Key Considerations |

Action Points |

|

Regulatory Compliance |

New regulations (e.g., EUDR, cadmium limits) |

Audit your products for compliance with the latest regulatory standards. |

|

Consumer Demand |

Health-conscious trends (e.g., protein, low sugar) |

Analyse sales data and trends (e.g., use Innova Market Insights). Test product prototypes with target consumers. |

|

Technology & Capacity |

Machinery upgrades, production scalability |

Evaluate existing capacity vs. demand growth. Prioritise upgrades to meet future market needs. |

|

Supply Chain & Partnerships |

Ethical sourcing, new partners |

Reassess current suppliers and seek new partnerships aligned with sustainability goals. |

|

Financial Impact |

ROI, budget allocation |

Use a decision matrix to evaluate each project’s ROI. Prioritise quick wins or long-term strategic benefits. |

Strategic Planning Essentials for Chocolate Innovation and Business Growth:

To begin effectively integrating these insights into your strategic decision-making, consider the following immediate actions:

- Establish a Clear Prioritisation Framework:

Use decision matrices or checklists to evaluate projects based on impact, feasibility, compliance, and ROI. - Cross-Functional Collaboration:

Convene strategic planning sessions regularly with leadership, finance, R&D, production, and marketing teams to ensure alignment on key decisions. - Proactive Market Monitoring:

To remain agile and responsive, continuously track emerging consumer trends, regulatory changes, and technological advancements.

💡 Ready to Strategically Position Your Brand for the Future?

Discover how our expertise in New Product Development, Turnkey Manufacturing, and Sustainable Sourcing can help you achieve your strategic objectives, navigate market complexities, and capitalise on growth opportunities.