QUALITY YOU CAN TRUST, BACKED BY SCIENCE

Ensuring exceptional chocolate starts with precision. At Luker Chocolate, we combine state-of-the-art technology, in-house expertise, and international certifications to guarantee quality, safety, and consistency—every step of the way.

Certifications backed by precision and expertise

Luker Chocolate integrates food safety, sustainability, and global standards to ensure exceptional quality at every stage of production. With internationally recognised certifications, we guarantee secure, sustainable, and high-performing chocolate that meets the evolving demands of both consumers and the industry.

OEA Certification

Our Authorized Economic Operator (OEA) certification, granted by the Colombian National Tax and Customs Directorate (DIAN), reflects our commitment to secure, transparent, and reliable international trade operations. This certification ensures that our company meets strict customs, tax compliance, and supply chain security requirements, reinforcing trust and facilitating global trade with our partners.

FSSC 22000

The FSSC certification allows us to maintain the highest food safety standards throughout our production processes. We ensure consistency in managing food safety risks, from sourcing raw materials to delivering the final product. With FSSC, we prove our dedication to producing safe, high-quality chocolate products.

ISO 14001

Our ISO 14001 certification reflects a deep commitment to sustainability, integrating responsible cocoa sourcing, energy efficiency, and waste reduction into every stage of production. By optimising resources, minimising environmental impact, and developing eco-friendly packaging, we align with global sustainability goals and evolving consumer expectations for transparent, planet-friendly products.

ONAC Accreditation

The ONAC accreditation officially recognises our compliance with rigorous national and international standards in testing, calibration, and certification. We are proud to be Colombia’s first laboratory accredited for cadmium determination, Salmonella detection, and lactose protein content.

ONAC is a member of ILAC (International Laboratory Accreditation Cooperation), which promotes global acceptance of test and calibration results through mutual recognition agreements among accreditation bodies worldwide.

Comprehensive quality assurance services tailored to you

We’ve designed our services to address the most critical aspects of turnkey chocolate manufacturing, from food safety to sensory consistency.

Setting the standard in chocolate manufacturing

Every chocolate we craft meets the highest safety and performance benchmarks. From taste and texture to food safety and sustainability, our comprehensive quality control ensures reliability at scale—so our partners can focus on innovation.

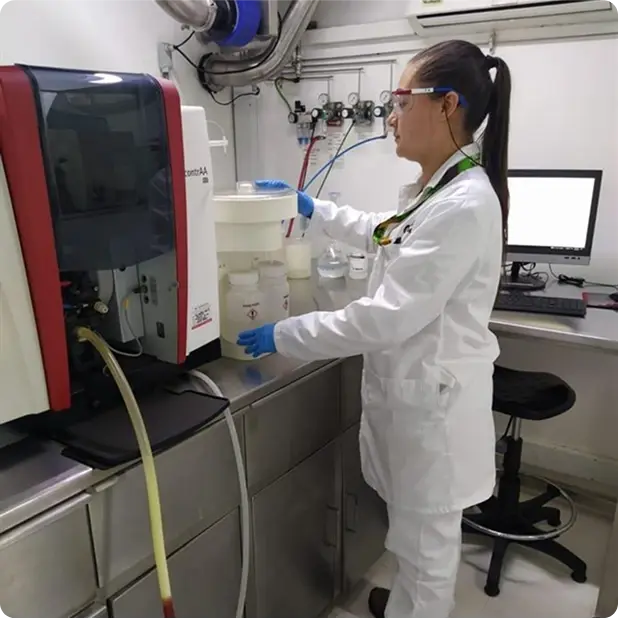

Advanced testing & in-house expertise

Luker is one of the few chocolate companies with an in-house, ONAC-accredited laboratory—offering unmatched control over quality and safety. Our expert team conducts rigorous testing, using advanced techniques like atomic absorption spectroscopy to monitor cadmium and lead levels, ensuring compliance with international regulations.

We test for:

- Physical & sensory analysis – Flavour, texture, colour, and tempering quality

- Chemical & microbiological safety – Heavy metals, pH, and contamination control

- Allergen management – Dedicated protocols for milk, soy, and nuts

- Ingredient authentication – Verifying purity and consistency

- Shelf life & stability – Ensuring freshness from production to consumption

With our fully equipped lab, clients don’t need additional suppliers for testing—streamlining processes and reducing complexity.

Rigorous heavy metal control

Consumers and regulators are increasingly focused on cadmium and lead levels in chocolate. We stay ahead with:

- ONAC-accredited laboratory – The first in Colombia accredited for cadmium determination in chocolate.

- Atomic absorption spectroscopy – Advanced techniques to measure heavy metal content with high precision.

- End-to-end monitoring – From cocoa sourcing to final production, ensuring compliance with global safety regulations.

Our FSSC 22000-certified protocols guarantee that every batch meets strict international thresholds, safeguarding both consumers and brands.

Strict allergen management for consumer confidence

Allergens are a critical concern in chocolate production. We maintain full control with:

- Dedicated allergen-free production lines – Minimising cross-contact risk for milk, soy, and nuts.

- Batch-by-batch testing – Ensuring compliance before products reach consumers.

- ONAC-certified lactose protein testing – As of November 2024, we are the first Colombian lab accredited to test for lactose protein content, reinforcing our commitment to dairy-free and allergen-sensitive solutions.

- Stringent cleaning & labelling protocols – Every product is clearly labelled (e.g., Dairy-Free, Soy-Free) to provide transparency to consumers.

With these internationally recognised controls, Luker guarantees safe, high-quality chocolate that meets the most demanding market requirements.

HOW CAN YOUR BRAND ENSURE HIGH-QUALITY CHOCOLATE?

With evolving consumer expectations around safety, transparency, and sustainability, brands must take a proactive approach to quality. Luker Chocolate provides tailored solutions to help businesses navigate these challenges.Luker’s advanced methodologies and international certifications allow brands to focus on growth and innovation—without compromising on safety.

FAQs

Heavy metals like cadmium and lead can naturally occur in soil and transfer to cocoa beans. Monitoring these levels is essential to ensure consumer safety and meet international food safety regulations.

Luker Chocolate employs atomic absorption spectroscopy in their laboratory to measure cadmium and lead levels. This rigorous sampling plan includes checks at various production stages, from sourcing and milling to the final product.

The European Union and other regulatory bodies have established maximum permissible levels for heavy metals, particularly cadmium, in cocoa products. Luker Chocolate adheres to these standards to ensure compliance and safety.

Yes, heavy metal levels are monitored at critical points, such as during raw cocoa processing, milling, and storage. This ensures that each stage aligns with strict safety limits.

If heavy metal concentrations exceed acceptable limits, products are held, and the source of contamination is investigated. This may involve reassessing supplier practices or modifying processing methods to reduce contamination risk.

Luker Chocolate implements comprehensive allergen controls, including production planning, dedicated equipment, and thorough cleaning protocols to prevent cross-contamination of allergens like milk and soy.

Luker monitors allergens commonly found in chocolate production, such as milk, soy, and nuts. Proper labelling (e.g.,"Dairy Free” or “Soy Free”) is also in place to inform consumers accurately.

Allergenic ingredients are carefully controlled and labelled at every stage. This includes designating separate production lines when possible, and following stringent cleaning and sanitation protocols between batches.

Luker trains personnel extensively on allergen risks and handling practices. This includes education on cleaning protocols, allergenic ingredient storage, and managing cross-contact during production.

Through rigorous testing and controls, including clear labelling and dedicated allergen-free production runs, Luker ensures products meet allergen safety requirements. Testing is conducted throughout production to verify allergen levels align with safe limits.

If contamination is detected, products are held, and a full review of handling procedures is conducted. Luker’s recall procedure is activated as necessary to ensure no affected products reach consumers.

Opportunities for Brands Using Free-From Chocolate in Bakery

What Brands Need to Know About Cadmium in Chocolate

How to control heavy metals and allergens in chocolate manufacturing?

Quality Testing in Chocolate Manufacturing to Ensure Consumer Safety

FAQs

At Luker Chocolate, we prioritise precision and excellence at every stage of production. Our in-house laboratory conducts over 100,000 tests annually, employing more than 90 analytical methods across physical, microbiological, and sensory evaluations. These rigorous quality control processes ensure that every batch meets the highest industry standards. Additionally, we work closely with trusted suppliers and maintain strong relationships to secure consistent, high-quality cocoa, guaranteeing uniformity across all our chocolate products.

Yes, all our chocolates are proudly single-origin, exclusively sourced from Colombia. We also offer single-region options that focus on showcasing the unique flavour profiles of specific regions, such as Huila, Tumaco, and Santander. Each origin reflects the rich characteristics of its region, shaped by its distinct climate, soil, and cultural heritage, providing an authentic and unique taste experience.

Absolutely! We collaborate closely with our clients to tailor chocolate formulations that meet their unique needs and market demands. Whether it’s adjusting cocoa percentages, sugar levels, or adding unique inclusions, our dedicated NPD team ensures the formulation aligns not only with your vision but also with evolving consumer trends. From initial consultation to finalisation, we support you every step of the way.

Luker’s Heritage portfolio features chocolates optimised for exceptional performance across applications, with carefully designed viscosity, tempering requirements, and melting points to meet diverse needs. Detailed technical specifications for each product can be found in the Heritage Portfolio brochure, which is available for download.

Our formulations are engineered for outstanding performance across a wide range of applications, including glossy bonbons, velvety ganache, and robust couverture. For bespoke requirements, we also develop tailored formulations that suit specific applications or consumer preferences, starting from certain minimum order quantities (MOQs).

Consistency is at the core of our manufacturing process. We use advanced equipment, adhere to standardised recipes, and implement rigorous monitoring throughout every production stage. This ensures uniformity in taste, texture, and quality across all batches, even in large production runs.

Luker Chocolate follows stringent protocols to prevent cross-contamination, including the use of dedicated equipment, rigorous cleaning between runs, and detailed ingredient tracking. Our laboratory’s accreditation for allergen detection, including lactose protein testing, ensures precise results and transparency. Combined with thorough labelling practices, we help clients meet consumer expectations for allergen safety and trust.

We provide comprehensive technical support, from troubleshooting to new product development. Our expert team collaborates with clients to ensure that formulations align with their equipment and facilities. Whether it’s adjusting machinery settings or offering guidance on process optimisation, we work closely to integrate new products seamlessly into production.