CHOCOLATE MANUFACTURING CAPABILITES

We combine tradition, innovation, and expertise to create tailor-made chocolate solutions. With a fully integrated supply chain and a dedicated R&D team, every product is designed to meet your brand’s unique needs.

Tailor-made chocolate manufacturing capabilities

Crafting bespoke chocolate products with a high level of customisation, ensuring that each creation aligns with your brand's vision and market demands.

Leveraging our expertise in cocoa origins, we design flavour profiles to match your product vision and source cocoa varieties that enhance taste and uniqueness.

From flavour development to texture refinement, our R&D team works with you to craft exclusive formulations that align with market trends and consumer expectations.

Offering a range of chocolate packaging solutions tailored to your brand identity, sustainability goals, and logistical requirements.

Precision-crafted moulds allow for distinctive chocolate designs, ensuring consistency and differentiation in the market.

Meeting cocoa regulatory requirements across different markets, ensuring your products align with local labelling, safety, and ingredient standards.

Flexible delivery terms tailored to your supply chain needs, ensuring smooth logistics and cost efficiency.

We guarantee consistency and excellence with rigorous chocolate quality control in our certified lab, exceeding industry standards.

Expert guidance on cocoa and ingredient selection to align with sustainability, flavour, and functionality goals.

A team of specialists working alongside your brand to innovate, refine, and perfect chocolate products for market success.

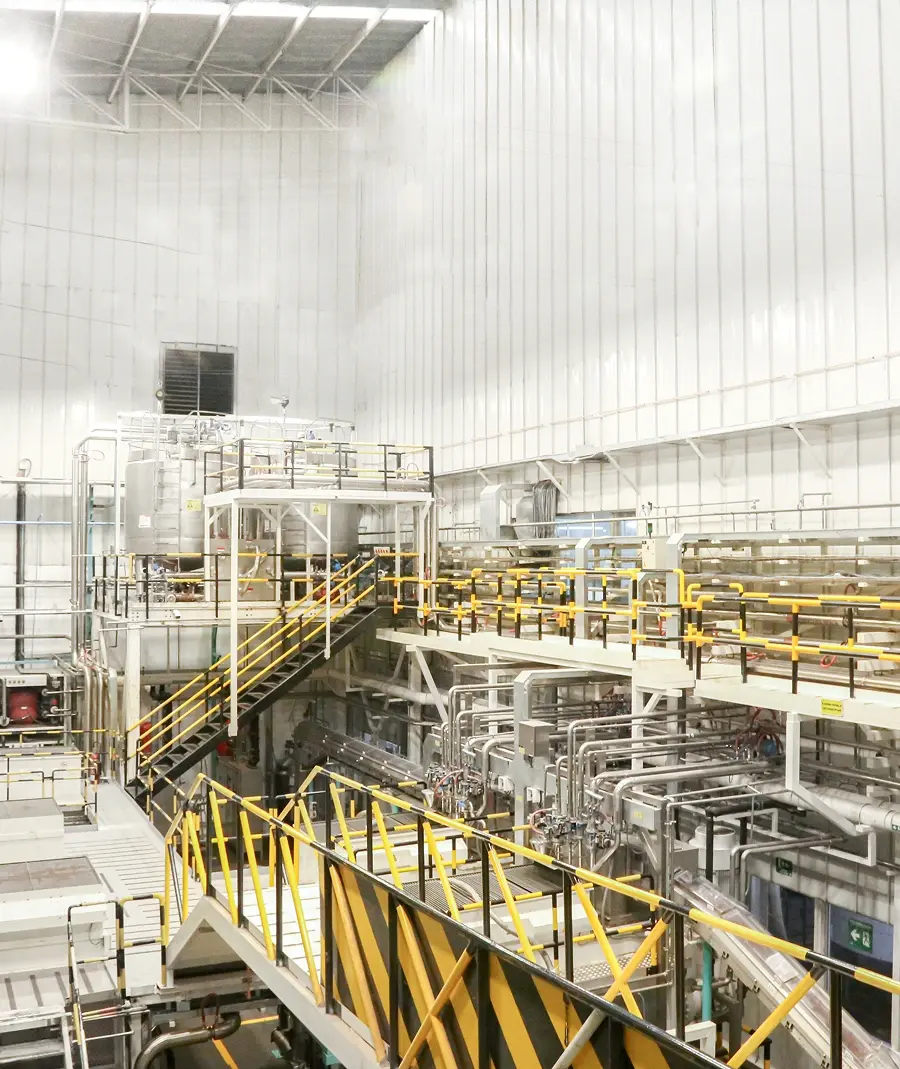

Scalable chocolate manufacturing solutions

Big ideas deserve bigger solutions. We empower your business with tailored production to meet evolving demands.

Traceable cocoa production

Our century-long expertise ensures ethical, fully traceable cocoa sourcing, strengthening your brand’s integrity and transparency.

From lab run test to selling on shelves

Our R&D team collaborates with you from concept to market, ensuring the right formulation, stability, and production scalability.

Organic & free from

Developing bespoke chocolate solutions that cater to the growing demand for organic, vegan, and allergen-free products. (MOQ: 4 tons for these projects)

Customisation for high volumes

A comprehensive chocolate manufacturing framework that allows for precise customisation while maintaining efficiency at scale.

Create your own products for:

- Snacks – Tailored chocolate solutions for bars, clusters, and coated treats.

- Chocolate bars – From classic to innovative formulations, designed for premium and mass-market brands.

- Bakery products – Chocolate inclusions and coatings developed to enhance baked goods.

How do we operate?

At Luker Chocolate, we blend our decades of manufacturing expertise with a deep understanding of your unique business requirements.

Whether you’re looking to create distinctive flavour profiles, meet specific dietary or sustainability standards, or scale production efficiently, we deliver tailored chocolate solutions designed to align with your goals.

Our precision and commitment to excellence ensure that every product meets the highest standards of quality, helping your brand stand out in a competitive market

FAQs

At Luker Chocolate, we combine decades of expertise with a deep understanding of your business needs. This allows us to deliver customised chocolate solutions with precision, ensuring high-quality products that align perfectly with your goals.

Yes! We specialise in developing distinctive flavour profiles tailored to your specifications, helping you create chocolate products that stand out and cater to your target audience’s tastes.

We are committed to precision and excellence in every step of the process. From sourcing premium cocoa to final production, we ensure that each product meets rigorous quality standards for flavour, texture, and consistency.

Absolutely! Whether you're looking to create organic, gluten-free, dairy-free, or allergen-free chocolate products, we can customise solutions to meet emerging dietary trends and customer preferences.

We prioritise sustainability by sourcing cocoa responsibly, working with ethical producers, and ensuring that our production processes are environmentally friendly, helping your brand meet sustainability goals.

We offer flexible solutions that allow you to scale your production from small batches to large volumes while maintaining quality and consistency, helping your brand grow efficiently and meet rising demand.

We continuously monitor emerging consumer preferences and trends, such as organic and free-from products, enabling us to innovate and develop bespoke chocolate solutions that cater to evolving market demands.

FAQs

At Luker Chocolate, we prioritise precision and excellence at every stage of production. Our in-house laboratory conducts over 100,000 tests annually, employing more than 90 analytical methods across physical, microbiological, and sensory evaluations. These rigorous quality control processes ensure that every batch meets the highest industry standards. Additionally, we work closely with trusted suppliers and maintain strong relationships to secure consistent, high-quality cocoa, guaranteeing uniformity across all our chocolate products.

Yes, all our chocolates are proudly single-origin, exclusively sourced from Colombia. We also offer single-region options that focus on showcasing the unique flavour profiles of specific regions, such as Huila, Tumaco, and Santander. Each origin reflects the rich characteristics of its region, shaped by its distinct climate, soil, and cultural heritage, providing an authentic and unique taste experience.

Absolutely! We collaborate closely with our clients to tailor chocolate formulations that meet their unique needs and market demands. Whether it’s adjusting cocoa percentages, sugar levels, or adding unique inclusions, our dedicated NPD team ensures the formulation aligns not only with your vision but also with evolving consumer trends. From initial consultation to finalisation, we support you every step of the way.

Luker’s Heritage portfolio features chocolates optimised for exceptional performance across applications, with carefully designed viscosity, tempering requirements, and melting points to meet diverse needs. Detailed technical specifications for each product can be found in the Heritage Portfolio brochure, which is available for download.

Our formulations are engineered for outstanding performance across a wide range of applications, including glossy bonbons, velvety ganache, and robust couverture. For bespoke requirements, we also develop tailored formulations that suit specific applications or consumer preferences, starting from certain minimum order quantities (MOQs).

Consistency is at the core of our manufacturing process. We use advanced equipment, adhere to standardised recipes, and implement rigorous monitoring throughout every production stage. This ensures uniformity in taste, texture, and quality across all batches, even in large production runs.

Luker Chocolate follows stringent protocols to prevent cross-contamination, including the use of dedicated equipment, rigorous cleaning between runs, and detailed ingredient tracking. Our laboratory’s accreditation for allergen detection, including lactose protein testing, ensures precise results and transparency. Combined with thorough labelling practices, we help clients meet consumer expectations for allergen safety and trust.

We provide comprehensive technical support, from troubleshooting to new product development. Our expert team collaborates with clients to ensure that formulations align with their equipment and facilities. Whether it’s adjusting machinery settings or offering guidance on process optimisation, we work closely to integrate new products seamlessly into production.